・Tatsuya Yamagata Senior VP General Manager

・Fumihiro Yanaka Senior VP General Manager

・Naoki Mizuno Senior VP General Manager

Our business activities are related with the United Nations Sustainable Development Goals (SDGs) in various ways.

For example, reduction of CO2 emissions involves company-wide energy saving activities and Green Chemistry promotion involves innovation in manufacturing processes.

The Takasago group has positioned the themes and goals set by the SDGs as priority issues regardless of business activity from research and development and procurement, production, and logistics supply chains to work styles and carries out efforts through its global CSR system.

In this feature section, the general managers of each of our business divisions will address matters including progress of business activities and issues in each field.

The Sustainable Development Goals (SDGs) were adopted by 193 member countries at the 2015 United Nations Summit as international goals to be achieved by 2030. In addition to signing the United Nations Global Compact in 2017, our company is working to solve global issues through careful examination of the contributions we can make through our business activities in order to achieve the 17 goals and the 169 targets of the SDGs.

Sustainability

We aim to strengthen our sustainability position through steady efforts to address each issue

Senior VP General Manager

Global Integration Headquarters and EHS Executive

Tatsuya Yamagata

In addition to environment, health, and safety, the CSR activities of the Takasago group address a wide range of issues, including respect for basic human rights and risk management. What is the sustainability promotion system and what are the specific efforts being carried out to promote sustainability?

Yamagata: The Sustainability Promoting Committee was established in 2017 to strengthen CSR activities throughout the entire Group while promoting global communication. Furthermore, our current One-T medium-term management plan (2018 to 2020) was positioned as a means of strengthening CSR promotion over a three-year period and focuses on global social issues such as climate change issues and respect for human rights.

In regard to climate change issues, the Takasago group’s corporate policy on climate change was released in April 2020 in line with the four TCFD*1 recommendations (Governance, Risk Management, Strategy, and Metrics and Targets) that global companies should comply with. As part of the policy, we are currently preparing to meet the Science Based Targets initiative criteria for setting targets. How to reduce CO2 emissions is an issue to tackle from here on. However, having received support with supply chain emission calculation provided by the Ministry of the Environment in 2019, it has become possible to calculate emissions for each category in Scope 3 (supply chain). We also started analysis ofthe current state of supply chain based emissions.

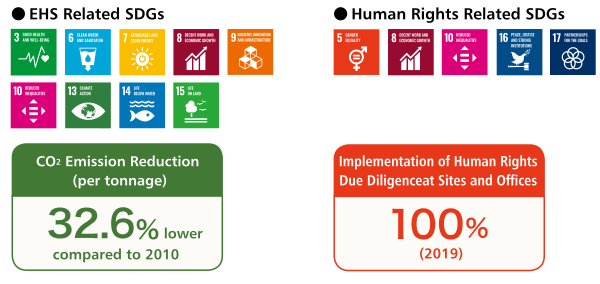

The Takasago group has traditionally considered reduction of CO2 emissions as an important issue. In the EHS100 Plan, which started in 2009, along with working on reducing water consumption and waste, reduction of CO2 emissions is a theme we have addressed as an environmental goal. As a result of continuous energy-saving activities and switching to energy with a low CO2 emission factor and electricity derived from renewable energy, we achieved 32.6% reduction per tonnage in 2019 compared to 2010. Raisinggoals designed to further promote our activities, we are striving to achieve 35% reduction per tonnage in 2020.

Human rights is specified as a materiality item. What initiatives are being taken by the Takasago group in the area of human rights?

Yamagata: The Takasago group formulated the “Takasago Group Human Rights Policy” in 2019. In order to embody this policy, we developed a process for human rights due diligence based on the Human Rights Due Diligence Implementation Guideline issued by Japan Federation of Bar Associations which covers a wide range of fields. We confirmed that there were no human rights violations or unintentional acts of complicity at any of our business sites in Japan or overseas.

Through these initiatives, we created a process to reexamine legal compliance in all departments and worked to visualize and ameliorate IT security vulnerabilities, etc. I would like to see the company continue to fulfill its responsibilities in various aspects as a global company.

*1: TCFD (Taskforce on Climate-related Financial Disclosures) was established by Financial Stability Board (FSB) in 2017. It emphasizes that companies recognize the risks and opportunities of climate change and incorporate them into their management strategies and recommends related disclosure to institutional investors and financial institutions that make ESG investments and loans.

Research and Development

Focusing on the development of raw material substitutes through the use of enzymes and biotechnology as well as the development of manufacturing processes that cause less environmental impact

Senior VP General Manager

Corporate Research & Development Div. and Supervisor for Fine Chemical Div.

Fumihiro Yanaka

Zero-Emission Challenge (creating the path to a carbon-free society through innovation)

It was announced at the TCFD Summit 2020 that Takasago group is recognized as a “company that has taken on the Zero-Emission Challenge” (company taking innovative efforts for the realization of a carbon-free society) as part of a project launched by the Ministry of Economy, Trade and Industry.

As for research and development, in the One-T medium-term management plan we aim for environmentally-friendly research and development with SDGs and GSC (Green Sustainable Chemistry) in mind. Celebrating our 100th anniversary this year, we are more strongly promoting research and development for the realization of a carbon-free society under the new theme “Symbiosis” (co-existing with nature) looking forward at the next 100 years.

Could you please tell us which SDGs you consider to be particularly important and about your recent achievements?

Yanaka: Our Research and Development Division is deeply involved not only in basic research and product development but also in the sustainability of natural resources that serve as the raw materials for fragrances and in reducing the environmental impact of the manufacturing process. Therefore, among the various SDGs, it is important to contribute to “9. Industry, Innovation and Infrastructure,” “13. Climate action,” and “15. Life on land.”

As part of this, the Research and Development Division also focuses on the innovation of manufacturing processes with Green Chemistry in mind. To realize sustainable manufacturing processes, we established the Process Development Laboratory in 2017 to explore safer, more environmentally friendly manufacturing processes, including compact and highly efficient continuous flow technology.

As a recent achievement in material development, we have actively utilized renewable raw materials and commercialized aroma ingredient products that cause less environmental impact, including our Sustainable Scent® series. Our unique asymmetric synthesis technology and catalyst technology are utilized in such material development. Furthermore, we started manufacturing new natural fragrance materials in 2019 as a result of incorporating biotechnology and focusing on the development of natural fragrance materials using enzymes and microorganisms.

For natural raw materials that are difficult to stably procure due to decreased production volumes, we have started to create substitutes for some of them. This effort includes searching for and converting aroma components in-house that highly contribute to the olfactory properties among raw materials.

As technological efforts that contribute to Green Chemistry, the development of catalysts that reduce the environmental impact and the expansion of continuous flow technology applications are attracting attention.

Yanaka: As for catalysts, we developed a technology in 2019 to replace the conventional method using a reducing agent with a method using catalytic hydrogenation reaction that produces less waste. With the aim of expanding the scope of application of continuous flow technology, we are considering using it not only for pharmaceutical intermediates but also for aroma ingredients.

Please tell us about themes and targets of focus for the future.

Yanaka: The Research and Development Division has positioned biotechnology as a key technology that promotes Green Chemistry to accelerate manufacturing with less environmental impact by integrating it with chemical synthesis technology. For example, we are conducting research and development to convert substances among raw material components that have a weak scent and cannot be used as fragrances into useful fragrance raw materials that have a pleasant scent by using biotechnology.

In the area of manufacturing process development, while moving forward in the development of catalysts and continuous flow technology, we will focus on the development of technologies that improve energy efficiency and reduce CO2 emissions in all manufacturing processes across the board.

In addition, we will also focus on human science, a field in which efforts are taken to improve quality of life. Such efforts include aroma-based stress reduction, sleep improvement, and cross-modal research between scent and other senses.

Procurement

Establishing and implementing systems and guidelines for the realization procurement at a global standard

Senior VP General Manager

Procurement Div., General Manager, Supply Chain Div., and Supervisor for Production Div.

Naoki Mizuno

Procurement Related SDGs

Please tell us about the progress being made in procurement activities.

Mizuno: For the past five years, the procurement department has accelerated establishing an environment aimed at the realization of a responsible sourcing. Examples of this are efforts that comply with ISO20400, a standard for sustainable procurement, and the development of TAKASOURCE, a supplier sourcing assessment tool.

In January 2020, we completed the creation of the Takasago Responsible Sourcing Policy. This policy is based on the auditing standards of SMETA*2 with reference to the international standard ISO26000 for social responsibility. In the future, we will utilize a self-evaluation questionnaire to provide our business partners with a better understanding about responsible procurement as well as conduct audits. We will also continue the audit using survey reports conducted from the viewpoint of safety and security by adding ethical items, and are considering whether to conduct field surveys or outsource field audits to third parties when necessary.

*2: SMETA (Sedex Members Ethical Trade Audit) is an audit standard developed by SEDEX (Supplier Ethical Data Exchange), an NPO membership organization established in the UK.

In regard to SDG “13. Climate action,” have the repeated large-scale natural disasters that have occurred in recent years had an impact on procurement?

Mizuno: For quite some time, large hurricanes have occurred in Florida, damaging grapefruit plantations which resulted in drastically reduced yields and spread of citrus diseases, making it difficult to secure natural oils. Even in Madagascar, the price of vanilla beans required for extract extraction soared due to the damage caused by cyclones. In addition, the drop in the water level of the Rhine River that occurred several years ago caused a stagnation in water transportation and a shortage of water for factories, affecting the supply of fragrance raw materials manufactured by chemical manufacturers along the river basin.

The Procurement Division eagerly responded to these issues by utilizing our global network, and although we were able to avoid complete shortages, we were unable to avoid price hikes, etc.

Please tell us about issues that require attention and future plans.

Mizuno: In today’s so-called “VUCA*3 era,” preparations using risk management are essential, and it is important to implement the PDCA cycle in a short period of time based on the hypothesis of risk aversion to strengthen the system. At the same time, keeping in mind that the procurement occurs thanks to our business partners, we will continue to strive for "symbiosis, mutual prosperity, and coexistence" by valuing interactive communication and relationships.

The mission of the Procurement Division is to become the cornerstone of the value chain that supports business growth and practice a responsible sourcing that gives consideration to the global environment, safety and health, laws and ordinances, human rights, local cultures, and just business transactions valuing a “connected spirit.” For this, we must focus on initiatives with more of an upstream point of view, regardless of whether it involves natural or synthetic materials. To that end, we will expand the possibilities of new procurement models, such as TaSuKI *4, which aims to strategically and sustainably procure raw materials, and TACMI *5, in which the procurement department is involved from the development stage to support development and manufacturing. At the same time, we will continue to promote initiatives for renewable raw materials and recycled containers.

*3 VUCA is a business term created in the US that stands for Volatility, Uncertainty, Complexity, and Ambiguity.

*4 TaSuKI (Takasago Global Procurement Sustainability Key Initiatives)

*5 TACMI (Takasago Global Procurement Arts & Crafts Mutual Interaction)

Production logistics

Increasing annual targets of reduction ratios of CO2 emissions and use of water resource and embarking on manufacturing and logistics reforms at major factories

VP General Manager

Production Div. and General Manager, Iwata Plant

Hiroyasu Kumamoto

Production logistics Related SDGs

Please tell us about the SDGs that are applicable to production and logistics and the main initiatives that you are taking.

Kumamoto: I think that “9. Industry, innovation and infrastructure,” “12. Responsible consumption and production,” and “13. Climate action” are applicable with “14. Life below water” and “15. Life on land” applicable to emission management.

Among related efforts, the Takasago group’s most important issue, climate change countermeasures (CO2 emission reduction), has been successful for the steady energy-saving activities of each factory, and, as reported in the CSR field at the beginning, the result exceeded the target.

In addition, as for precious water resources, we achieved, just as with energy, 20% reduction in 2018 compared to 2010 which was further reduced to 22.3% (actual value) in 2019. We have set the 2020 reduction target at 25% reduction.

In contrast, the Iwata Factory, which is 51 years old, operates a synthesis plant that consumes a lot of energy. The factory’s facilities related to menthol, which is its main product, have become significantly decrepit, making systematic reorganization indispensable. In particular, the energy consumption of the deep cooling process accounts for 23% of the total energy consumption by the factory. As a result, the initiative promotion team is working to save energy and improve the working environment by reviewing the manufacturing process.

As for the logistics field, the Takasago group established the Corporate Logistics Policy in April 2020 in accordance with the basic management policy of giving consideration to the global environment and preserving local communities. We are accelerating the speed of related efforts.

Please tell us about issues and initiatives that the division should focus on in the future.

Mizuno: As a response to climate change issues, we are working to reduce CO2 emissions in the supply chain in Scope 3, Category 4 “Upstream transportation and distribution.” As an example, the construction of a new factory in Hiroshima Prefecture in the wake of the fire at the Hiratsuka factory has dispersed the flavor production bases to eastern and western Japan, increasing the distance between bases for distribution to the Hiratsuka Distribution Center, which also serves as a warehouse. In order to make improvements, we are working to improve efficiency by now having some products shipped directly from the factory to the delivery destination.

We are also considering storing globally supplied products, such as menthol, at our overseas locations. By distributing inventory to major locations through organized container transport, we can expect to avoid risks from natural disasters, reduce the environmental impact by improving transportation efficiency, and improve delivery speed. To improve the efficiency of logistics, I believe that reforms utilizing partnerships with other companies are what is needed for adapting to times of rapid change. As part of this, we will verify the functionality of the 24-year-old Hiratsuka Distribution Center and review our distribution locations as we also consider outsourcing in order to realize more efficient transportation and delivery.

Creating the Future

-Response to Covid-19 and formulating a vision for sustainable growth-

Response to Covid-19 and formulating a vision for sustainable growth

Yamagata: The Covid-19 pandemic has caused a significant decline in the global economy, and our company is also affected by the pandemic in business areas such as fragrances for luxury items. Business for food flavors and fragrances for daily necessities, such as soaps and detergents, has remained relatively stable.

Mizuno: In regard to procurement activities, however, due to lockdowns in various countries to prevent the spread of infection, manufacturing and distribution by suppliers have been delayed, raising concerns about shortages and delays in raw material supply. For this reason, we supplement our supply and demand forecasts as soon as possible and work with procurement managers and related parties in each country to avoid risks and ensure stable procurement of raw materials.

Kumamoto: The pandemic had no direct impact on production division due to thorough infection prevention measures. As for an indirect impact, there were delays in the arrival of overseas raw materials due to delays in distribution. However, with some exceptions, we have secured sufficient inventories and have not made any major changes to our production plans.

Yamagata: Regarding employee safety measures, we have introduced a staggered work system for employees who commute by public transportation in Japan, which leads to flexible working styles while avoiding congestion and infection. In addition, we have introduced telecommuting while giving due consideration to security and are able to operate online-based meetings smoothly. When the Japanese government issued a state of emergency in April, up to 90% of employees at our headquarters worked from home.

Please tell us about future related initiatives and goals.

Yamagata: We kicked off the Global SAP*6 Project in February 2020 and are working to integrate the core systems of our major overseas locations over the next few years. Through this project, business flow will be unified in a way that enables Takasago Best Practices, which will increase the flexibility of transfer between locations and human resource utilization, and strengthen the Business Continuity Plan (BCP) system so that the company can adequately respond to natural disasters. Among the SDGs, we are carrying out initiatives falling under “8. Decent work and economic growth.” As the first step, we plan to introduce this system first at overseas offices and then put it in operation on a global level in five years.

The reason why such a project can be promoted is because the procedures for establishing corporate policies for each department globally, developing guidelines, and implementing them are spread throughout the Takasago group. This is the result obtained through GP-3 and One-T, and it is also an essential condition for promoting sustainable management.

The Sustainability Promoting Committee is playing a central role in the formulation of "Sustainability 2030" (tentative name), which is the plan following the EHS100 Plan based on the processes built up in One-T. With the SDGs in mind, we are pursuing a good balance of environmental, social, and economic activities while deepening discussions to contribute to solving global issues.

There are a wide variety of initiatives that we should strengthen, such as environmental issues, human rights issues, occupational safety, human resource development, and social contribution activities. We will continue to carefully resolve each issue in line with our action plan.